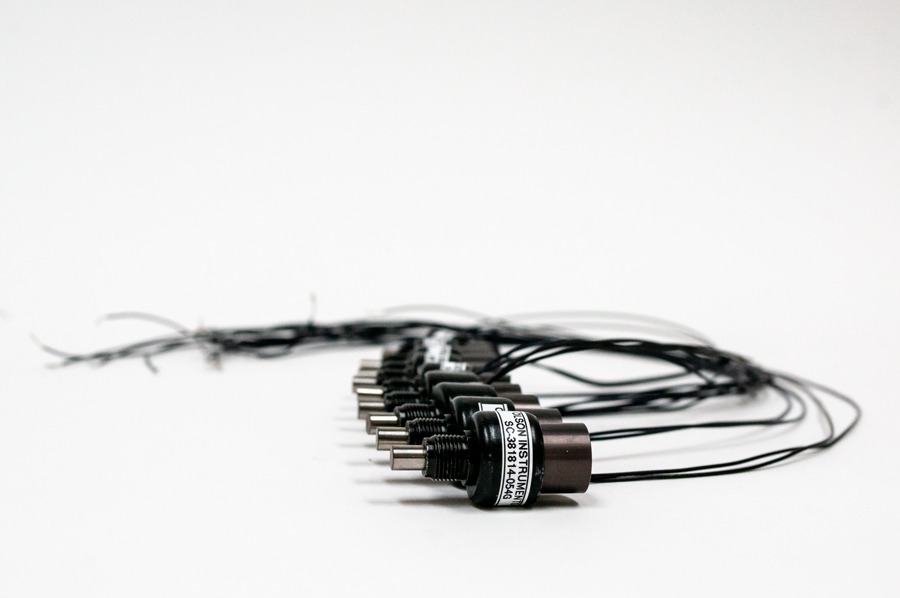

Impact Solenoids

These high quality impact solenoids are utilized in many different applications by our customers around the world. Our solenoids have been employed in the testing of turbines and generators and have been used in assembly equipment and robots manufactured in Europe and Canada. We can ship worldwide and we are able to ship a range of quantities. We are committed to quality: we test the product performance of each impact solenoid and we only use UL recognized components.

Once designed, we model and test new solenoids in our facility in Wheat Ridge, Colorado, before shipping them to our customers for application testing. The unit is designed to accept different size and weight plungers as your requirements may dictate. Contact us today about your order.

Produced and Protected by US Patents 4,272,748 4,200,401 & 5,527,117

For complete details about any of our products, call our toll free number at 1-888-423-1214 or email Olson Instruments:

Key Features & Specifications

| Projected life of 125 million cycles | Quiet actuation ideal for office environment |

| Interfaces with plastic or metal daisy wheel | Unique patented construction minimizes bounce to precise limits |

| Lead wire length variable | Simple to install and adjust |

| Force: .011 to .019 joules at 5 amps typical | Stroke: .150" x 250" travel |

| Insulation Resistance: 1000 megohms | Dielectric Strength: 500 VRMS |

| Coil Resistance: 1.9 ohm + .1 chm @ +20 C | Finish: Zinc with black chromate finish |

| Weight: 1.14 oz. (32g) incl. Plunger. Plunger wt. 14 oz (4.g) | Frequency: 40 Hz with .150" stroke |

Environmental Requirements

| Life: 125 million actuations projected | Operating Temperature: + 70 C surface max. |

| Humidity: 95% | Electrical Hook-up |

| 28 VDC + 5 VDC with 1 to 3.5 ms on time | 1/10 duty cycle |

| 4-6 amps constant current | 5 watts input procedures an 80 rise at 25 C ambiant. The trial coil temperature should not exceed 105 C (rise plus ambiant) |

| The solenoid was mounted on a 3" x 3" x 1/8" aluminum plate for test purposes | Current, on time and duty cycle must be controlled to insure that the maximum coil temperature is not exceeded. |